The Thriving Landscape of 3D Printing Business

Introduction

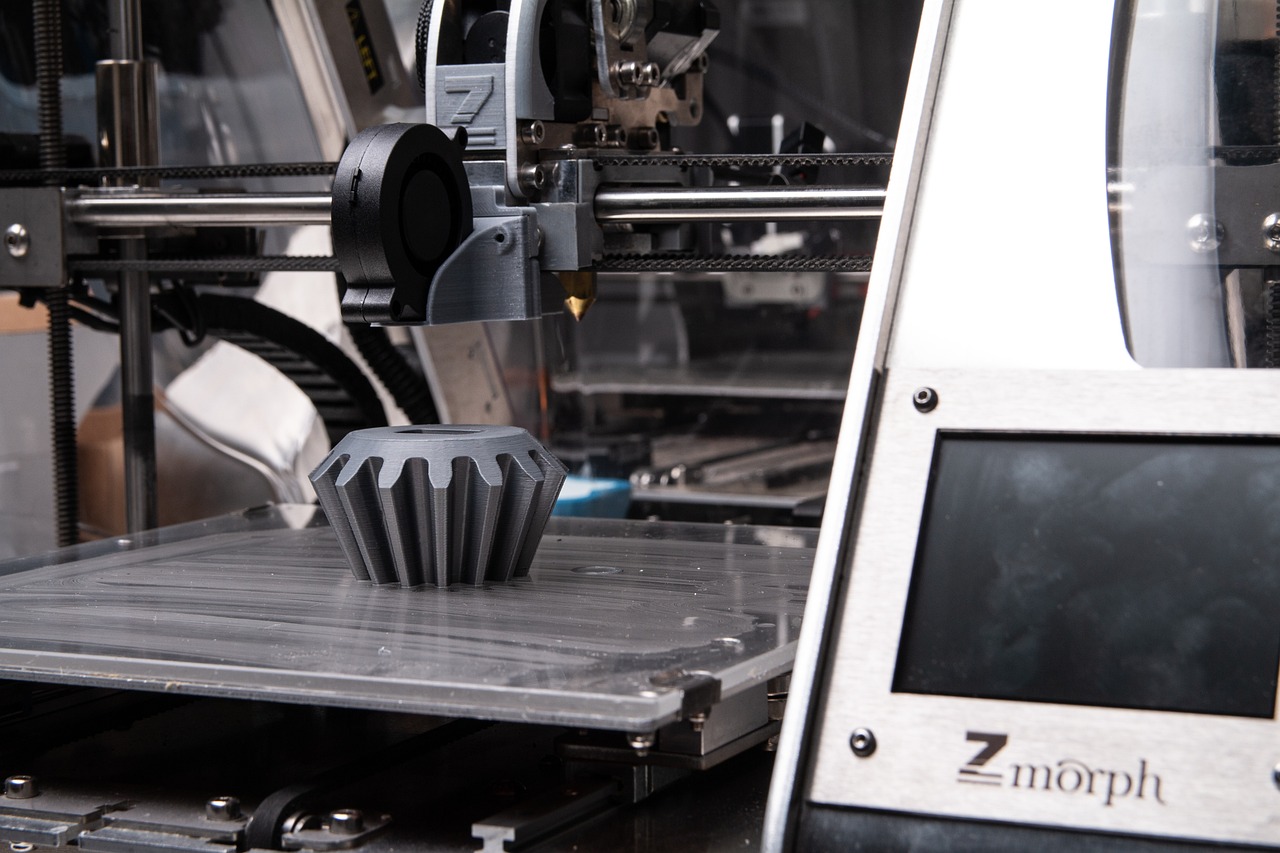

The 3D printing industry has undergone a remarkable transformation in recent years, evolving from a niche technology into a thriving global business sector. This revolutionary technology, also known as additive manufacturing, has opened up new possibilities across various industries, from healthcare and aerospace to automotive and consumer goods. In this article, we will explore the dynamic world of 3D printing, its rapid growth, emerging trends, and its profound impact on the business landscape.

The Evolution of 3D Printing

The origins of 3D printing date back to the 1980s when Charles Hull invented stereolithography, a process that laid the foundation for additive manufacturing. However, it wasn’t until the 21st century that 3D printing gained significant traction. Early applications were primarily limited to prototyping and rapid tooling. As the technology advanced, the scope expanded exponentially.

Rapid Growth and Diverse Applications

Today, 3D printing has become an integral part of several industries, and its applications continue to diversify. In the medical field, it has revolutionized prosthetics, custom implants, and even the fabrication of human organs. In aerospace, it has led to lighter and more efficient aircraft components, reducing fuel consumption and emissions. In architecture and construction, it enables the creation of intricate building designs with enhanced structural integrity. The automotive industry utilizes 3D printing for parts production and even the development of entire vehicles. Additionally, fashion, art, and consumer goods industries have embraced 3D printing for custom designs and limited-edition products.

Key Drivers of the 3D Printing Business

Several factors have contributed to the rapid growth of the 3D printing business:

Technological Advancements: Continuous innovation in materials, hardware, and software has expanded the capabilities of 3D printing, allowing for more complex and high-quality output.

Cost-Efficiency: 3D printing has become more cost-effective as the price of printers and materials has decreased, making it accessible to a wider range of businesses and individuals.

Customization: The ability to create highly customized products has attracted industries looking to cater to individualized consumer preferences, driving demand for 3D printing services.

Sustainability: 3D printing promotes sustainability by reducing material waste compared to traditional manufacturing processes.

Supply Chain Resilience: The COVID-19 pandemic highlighted the importance of resilient supply chains. 3D printing offers a decentralized manufacturing approach that can mitigate disruptions by enabling local production of critical components.

Challenges and Opportunities

While the 3D printing business has seen tremendous growth, it faces challenges that need to be addressed for sustained success:

Intellectual Property Concerns: The ease of digital file-sharing raises concerns about intellectual property theft and unauthorized replication of copyrighted designs.

Material Limitations: Despite significant advancements, 3D printing materials still have limitations in terms of strength, durability, and heat resistance, which limits certain applications.

Regulatory Hurdles: Industries like healthcare and aerospace face strict regulatory requirements, and 3D printing technologies must comply with these standards.

Skills Gap: There is a shortage of skilled professionals who can operate and maintain 3D printers and create complex 3D designs.

Post-Processing Challenges: Many 3D printed parts require post-processing, which can be time-consuming and costly.

However, these challenges also present opportunities for growth. Companies specializing in 3D printing services, materials, and software are poised to address these issues and drive innovation.

Emerging Trends

Several trends are shaping the future of the 3D printing business:

Bioprinting: The field of bioprinting is advancing rapidly, with the potential to revolutionize healthcare by printing living tissues and organs.

Metal 3D Printing: Metal additive manufacturing is becoming more accessible and is poised to disrupt industries like aerospace and automotive with stronger, lightweight components.

Mass Customization: Businesses are increasingly adopting 3D printing to offer personalized products, from customized footwear to tailored medical devices.

Sustainability Focus: Environmental concerns are driving the development of more sustainable materials and recycling solutions for 3D printing.

Conclusion

The 3D printing business has evolved from a novel technology to a transformative force across multiple industries. Its growth is driven by technological advancements, cost-efficiency, customization, sustainability, and supply chain resilience. Despite challenges, the future of 3D printing appears promising, with opportunities in emerging fields like bioprinting and metal additive manufacturing. As the industry continues to mature, it will reshape traditional manufacturing processes and create new possibilities for businesses and consumers alike.